Laser welding is a joining technique that offers multiple advantages such as resource-friendly production of small components with complex geometries and serves as a cost-effective alternative to traditional methods. The process works by directing laser beams through a laser-transparent material, which then melts the underlying portion of a laser-absorbing component. The heat from the melted plastic is transferred to the laser-transparent part, forming a strong weld line as the materials cool. Essentially, successful laser welding relies on the combination of a laser-transparent material and a laser-absorbing counterpart.

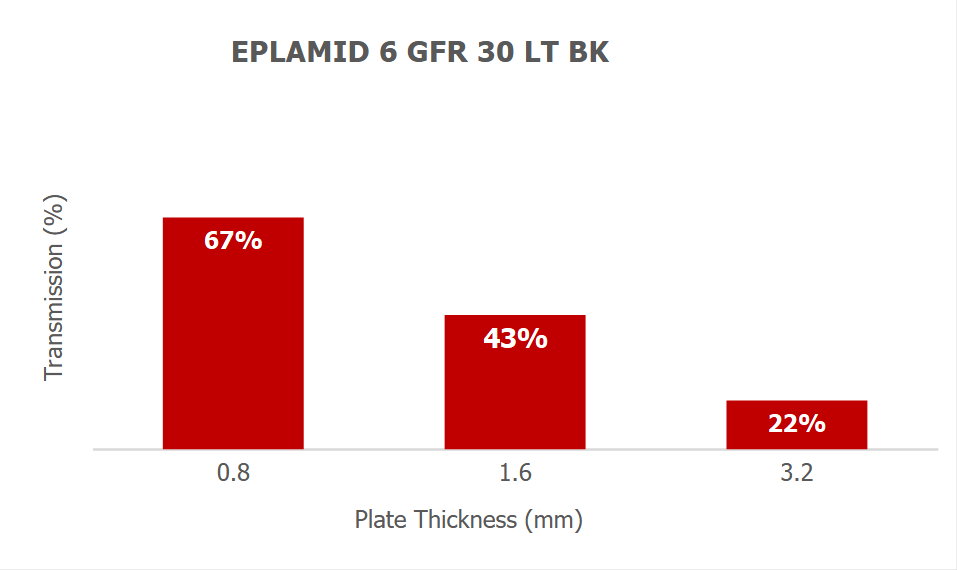

EPSAN's EPLAMID LT (Laser Transparency) series provides an optimized solution for laser transmission welding applications. Examples of improved optical properties of EPLAMID LT grades are shown below. Transmission has been tested using a wavelength of 980 nm.

EPSAN aims to contribute to the advancement of the engineering plastics sector by continuously delivering innovative solutions.

Laser Welding Optimized EPLAMID 6 GFR 30 LT BK

EPLAMID 6 GFR 30 LT BK is a 30% glass fiber reinforced compound utilized across various industries, offering a balanced combination of thermal and mechanical properties. This material is laser weldable and lubricated for injection molding.

A transmission of 67% at a plate thickness of 0.8 mm is possible (Fig. 1).

Fig.1: Transmission of EPLAMID 6 GFR 30 LT BK

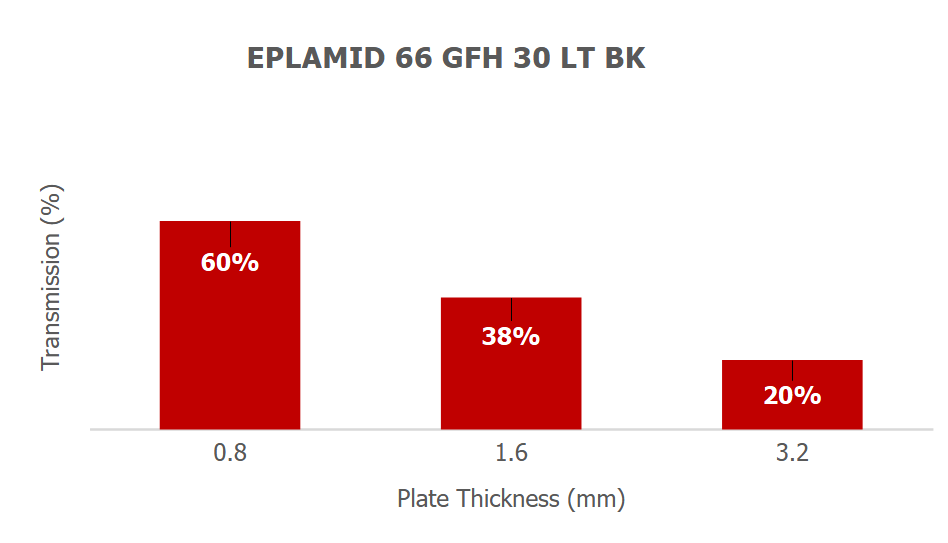

Hydrolysis Resistance and Laser Weldable EPLAMID 66 GFH 30 LT BK

EPLAMID 66 GFH 30 LT BK is a high-performance material specifically designed for industrial applications. It is a reinforced version of polyamide 66 with 30% glass fiber, resisting hydrolysis and hot oils, and is particularly suitable for laser welding applications. EPLAMID 66 GFH compounds find extensive use in automotive areas such as under-the-hood applications, providing an excellent balance of thermal and mechanical properties along with long-term heat and hydrolysis resistance.

It exhibits a transmission of 60% at a laser wavelength of 980 nm and a test specimen thickness of 0.8 mm (Fig. 2).

EPSAN continues to play a leading role in the industry by offering innovative materials that meet sustainability and performance requirements.

Fig.2: Transmission of EPLAMID 66 GFH 30 LT BK